Silver-colloid creator equipment

user’s manual.

The equipment may be used only with distilled water

purchased in pharmacy, and 99.99% pure silver electrode!

Following connecting the power source, touching the

electrodes is prohibited!

You can produce very high quality

solution in the required density.

In order to produce high quality colloid, it is

important to provide 1 mA current on the electrode, and the equipment shall

automatically switch the polarity of the electrodes.

Below 1 mA current, the time required to produce

colloid significantly increases. Above 1 mA, the size of the silver ‘particles’

will be higher in the solution.

Use of the equipment:

Connect the silver electrodes to the equipment.

Locking screws of the silver electrodes may be

tightened manually.

Do not use screwdriver, because it may press and

damage the electrode.

Technical parameters:

Electrode voltage: 60V DC

Electrode current: set to 1 mA

Polarity switch: in every 60 seconds

Caution!

99.99% pure silver electrode is mandatory!

Electrodes from uncertain sources shall not be used!

Jewellers do not use silver of this kind of purity.

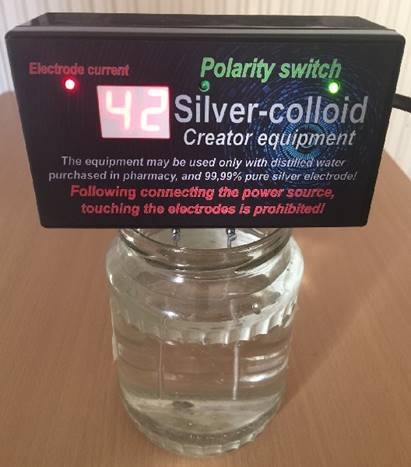

Place the prepared equipment onto a glass filled with

distilled water:

To produce silver colloid, use distilled water purchased

in the pharmacy!

Neither pipe-water, nor water purified with osmosis

water purifier shall be used!

If the electrodes are in water, the LED ‘Electrode

current’ lights.

Green LEDs (showing polarity switch) switch in every

60 seconds.

Depending on the quantity and the temperature, colloid

production may take 6-48 hours.

You can check the process using a TDS meter.

The process may be accelerated by heating, but it

shall never exceed 56 °C!

Measuring the density of colloid:

Immerse the TDS meter into colloid following switching

on, then You can read the solution’s density on the display.

Measuring accuracy: 1 ppm (1mg/l).

Distilled water purchased in the pharmacy has ‘0’

density.

Colloid solution shall be prepared to 10 ppm density.

More is not better, do not use internally above 20

ppm!

Keep out the produced colloid of light!

You can produce excellent quality solution (colloid)

with high silver content using the equipment. The size of these particles are 3-5 nm.

The size of the particles depends on following the

instructions, that shall be followed when producing colloid silver.

Colloid silver production using this equipment is

longer compared to other equipment, however, its quality is excellent, thus

effective annihilation of fungi, bacteria and viruses are ensured. The colour

(so the quality) of the received silver colloid does not change when stored

appropriately.

The equipment utilizes timed intervals, making jumping

polarity switch on the silver electrodes. These electrodes are made of 99.99%

pure silver.

How the best quality is ensured? Beside the above

mentioned time intervals, by a very accurate and constant current load on the

electrodes, which is automatically and continuously changing due to the

silver saturation of the colloid solution.

Production of colloid silver is very simple using this

equipment.

Use:

The equipment is pre-programmed, CPU-controlled, its

operation is very simple.

Spill distilled water into a glass of 0.4-0.5 litre

capacity. Rinse the glass with distilled water first. Connect the silver

electrodes to the equipment and rinse with distilled water. Place the equipment

with the electrodes to the side of the glass (see on the image). Connect the

equipment to a free wall socket. If the electrodes are in water, the ‘electrode

current’ red LED lights, production of the colloid silver is started.

Green ‘polarity switch’ LEDs switch each other in

every 60 seconds.

The producing process is 6-48 hours (depending on the

water quantity, temperature and quality). The process may be accelerated by

heating the distilled water (to max. 56 °C).

The received solution is recommended to filter through

a simple coffee filter paper.

The produced colloid silver is outstanding compared to

the other colloid silver solutions, by annihilating pathogenic micro-organism

and offering minimal efficiency loss in case of longer storage.

The quality of the used distilled water needs to be

emphasized. The pre-requisite of producing excellent quality product is having

outstanding quality water and very pure silver electrodes.

Equipment producing colloid silver in some minutes or

hours are unable to produce the same quality solution, so the efficiency of the

unprofessionally produced solution is very limited and controversial.

Unfortunately there are more and more ads where a simple notebook

charger is sold to produce silver colloid, but I have also seen 3 pieces of 9V

batteries connected in line as ‘colloid producers’.

If You trans-illuminate the colloid silver in complete

darkness using a laser pointer, the visible laser beam shows the fine trace in

the colloid silver. This fine trace exactly refers to the high quality of the

produced colloid. This phenomenon is called TYNDALL EFFECT, which is an

important tool to measure the quality of colloid silver.

Benefits of quality colloid silver produced by the

equipment:

- the smaller the particles, the higher the

concentration (ppm) on its total surface, meaning higher efficiency against

pathogens.

- the smaller the particles, the faster the colloid

moves in the entire body and leave it thanks to the digestive system.

If the particles are larger (low quality colloid

silver solution), it might be accumulated in the liver.

Storage:

Store the ready colloid silver in dark bottle, and

avoid contact with strong electro-magnetic field sources (such as computer,

television, mobile phone, microwave oven etc.) and direct sunlight. It shall

not be frozen!

Maintenance of the electrodes:

Always wipe the electrodes with a paper wiper after

use. Clean the electrodes only mechanically, never use liquid detergents. A

simple sponge with rough surface used to dishwashing is perfect for this

maintenance.

The clarity of the electrodes and the purity of the

distilled water are required to successfully produce high-quality colloid

silver, which may be very useful to improve and maintain Your health.

The colloid silver is known for being chemically

neutral to all liquids and medicines, including antibiotics.

It does not irritate the digestive system, meaning

that colloid silver may be used by people suffering in acute stomach acid

problems, spasm and other digestive problems.

Colloid silver research revealed, that most bacteria

and viruses are unable to develop self-defence mechanism against it.

Colloid silver kills not only pathogens, but

body-friendly bacteria as well (just like antibiotics). Therefore, these

bacteria shall be strengthened by taking probiotics.

Application of colloid silver in the official medicine

in Europe and in the USA showed up between 1933 and 1939, as a primary medicine

at some diagnoses, prior to the invention of antibiotics:

- acne

- arthritis

- irritation

- gastritis

- burns

- diabetes

- colitis

- cystitida

- eczema

- peptic ulcer

- mildew in the bowels

- rheumatism

- rhinitis

- dermatitis

- pneumonia

- psoriasis

- infectious diarrhea

- keratitis

- herpes

- skin fungus

- otitis media

- prostate enlargement

- blepharitis

- discharge of nasal cavity

- flu

- pancreatitis

History of silver

therapy:

The ancient Indian medicine noticed the anti-microbe

properties of silver first. Common application of silver as anti-microbe tool

was first used in the Roman Empire. Foods were stored in silver vessels in

every patrician houses, silver coins were put into milk and fluids. This

tradition was also known in the medieval ages. Use of silver cutlery and pots

were quite common. Even the holy water pots were made of silver in the church,

so the water was practically disinfected in them.

The best period of colloid silver was between the two

world wars. Silver was used as medicine to cure infectious diseases at first,

orally or intravenously. However, during the World War II, sulfonamides,

and then antibiotics showed up on the market.

Another condition was against colloid silver, that

since the ‘60s, natural substances was not allowed to patented in pure forms as

medicines.

So

nobody had got exclusive rights to develop, manufacture and distribute them.

This fact was also responsible to prefer antibiotics

rather than silver, which is a symbolic transition from medicines to great

business.

In 1993, information were

revealed about the astronauts equipment, causing a new interest against colloid

silver. It has become public, that both American and Russian astronauts

(cosmonauts), so people paying much attention on their health, fly Universe

with colloid silver sets, which are for widespread healthcare and hygienic use.

In 1997, it has become public, that the chief medical

officer or US Ministry of Defense trusted a special

professional group to find those most efficient anti-viral, anti-bacterial and

anti-septic substances, that are easily available in military operations – the

winner was the colloid nano-silver!

Application methods of colloid silver:

The most efficient method for internal use is to drink

silver in the morning and in the evening, while taking probiotics in the form

of yoghurts or tablets/fluids. Dosage of colloid depends on the ppm

concentration of the solution.

You may perform mouth rinse – which removes halitosis

and plaque bacteria. Throat and nasal cavity rinse are very efficient too.

You may perform vagina rinse, anus disinfection or ear

cleaning.

It is also excellent for external therapy of acne,

rashes, eczema, bruises and insect bites.

Colloid silver belongs to the most effective fluids if

speaking about fungi, particularly in the digestive tract. Combination of enema

and drinking colloid silver significantly supports human body suffering in

fungus infection.

In case of pets, we can dab wounds and rashes with

colloid silver, or disinfect their toys and bowls.

Even infected house flowers may be watered with

colloid silver. Put some drops into the water, and You will see, that the plant

remains fresh longer.

Colloid silver, the natural antibiotics

The quantity effect of silver trace element is

defensive and improves Your immune system. Minerals of colloid solution have

98% absorption rate, compared to the 40-60% value of tablets. Colloid silver is

a pure metal silver diluted in distilled water, which can be purchased in the

pharmacy. The size of the particles are between 3 and

5 nm. The size of a virus is 15-150 nm, while bacteria vary between 350 and

1000 nm. Colloid silver may directly enter into the pathogens, efficiently

annihilating them.

High-quality colloid silver:

- Safe

- Non-toxic

- Works as antibiotics

- Kills more than 650 pathogens

- Kills fungi and mildew

- Supports cell’s development

- Is not stored

- Does not irritate mucous

- Does not cause addiction

- Does not contain free radicals

- Cleans and disinfects water

- Has anti-inflammation effect

- Disinfects

- Enters directly into the tissues

- Does not irritate eyes

- Does not react with other medicines

- Strengthens immunity

- Safe during pregnancy or nursins

- Colourless

- Odourless

Purchase options:

- Ready-to-use, tested equipment with 2 years of

warranty: 80 EUR

- 99.99% pure silver electrodes, 2 pcs of 10 cm length

with 2 mm diameter: 25 EUR

- Digital TDS meter: 12 EUR

E-mail: colloid@morvaiferenc.hu

The equipment is not suitable to diagnose, treat, cure

or prevent any diseases. Specification and effects may vary. In case of

application during taking medicines, it is recommended to consult with a

professional. Silver colloid may

complement medical therapy. If You have any medical condition, consult with

Your general practitioner!

Update: July

1, 2023.

In

the recent period, distillation devices have become

available at favorable prices, and as a result, many

people have made purchases. However, they are

complaining that they are unable

to produce water with "0" purity using these

devices.

Here,

I will share how I make distilled

water using such a distillation device:

The

device needs to be filled with

4 liters of water, and at the end, approximately

2.5 liters of distilled water will be obtained.

At my home, the tap

water has a PPM measurement

of around 250-300. I filter this

water through a reverse osmosis water purifier, which reduces the

PPM to 13-18.

I

boil this 13-18 PPM water in an electric kettle and pour it hot into the distillation

device. I pre-boil

the water because the distillation

device operates at 750W, and if I pour cold water into

it, it will

take a long time to heat

up. With the electric kettle,

it quickly reaches the boiling

point, and then I pour the hot water into

the distillation device. After a few minutes of starting the device, it

begins to drip the distilled

water.

Now comes the important

part:

I want to emphasize that I did not come

up with the

method of producing high-quality distilled water. I am simply applying the knowledge

and experience of experienced

distillers.

At the beginning of the distillation process, the dripping water

is not suitable for collection. So I place a glass

under the device to collect

the distilled water. When there

is enough water in the glass, I use

a TDS meter to measure it.

As long as the TDS meter

shows a value other than "0," I repeat the process of placing a clean glass under the

distillation device and measuring the water

that comes out.

Once the water coming out of the device reads

"0" on the TDS meter, I place a container underneath it, and from that

point on, only pure "0" PPM water will be collected.

If the first 1-1.5 deciliters of water at the

beginning are not removed but

left in the collection container, it will compromise

the overall quality because in many cases, this initial

portion is of lower quality than the

water poured into the distillation

device.

For the production of silver colloid, it is mandatory to have "0" PPM water!